How to Properly Maintain Excavator Parts: Strategies for Increased Longevity

Maintaining excavator parts is essential for ensuring the longevity and efficiency of the machinery. As heavy-duty equipment, excavators are subject to intense operational demands, which makes meticulous maintenance imperative to their performance. We understand that by adhering to a comprehensive maintenance routine, we can help prevent costly repairs and extend the lifespan of the excavator parts. This involves regular check-ups, cleaning, and immediate attention to any wear and tear.

Following the manufacturer’s maintenance schedule is vital. This schedule includes the timely replacement of fluids, filters, and worn parts. Excavators often encounter undercarriage issues, but we can prevent these problems by keeping tracks clean and at the proper tension. Training our employees in proper operation techniques and ensuring thorough inspections of buckets and teeth also contribute to reducing strain on the excavator parts.

Key Takeaways

- Maintaining excavator parts prevents costly repairs and extends the machinery’s life.

- Manufacturer guidelines and regular maintenance schedules are critical.

- Proper operation and component care are fundamental to excavator upkeep.

Understanding Excavator Maintenance

Proper maintenance of excavators is fundamental in extending their lifespan, ensuring safety, and maintaining efficiency and productivity on construction sites. Let’s explore the key tasks and the value of regular inspections and preventive maintenance.

Key Maintenance Tasks

We must address a set of maintenance tasks to uphold the excavator’s condition and functionality:

- Undercarriage Cleaning: After each use, we need to remove dirt and debris to prevent buildup, which could lead to excessive wear.

- Engine Care: An excavator’s engine requires regular oil and filter changes, fuel system inspections, and coolant level monitoring to preserve its performance and fuel efficiency.

- Hydraulic System Maintenance: Since the hydraulic system is crucial for the excavator’s movements, we must regularly inspect for leaks and change the hydraulic oil as per the manufacturer’s guidelines.

Regular Inspections and Preventive Maintenance

Preventive maintenance is the key to mitigating future issues and wear and tear. It encompasses the following:

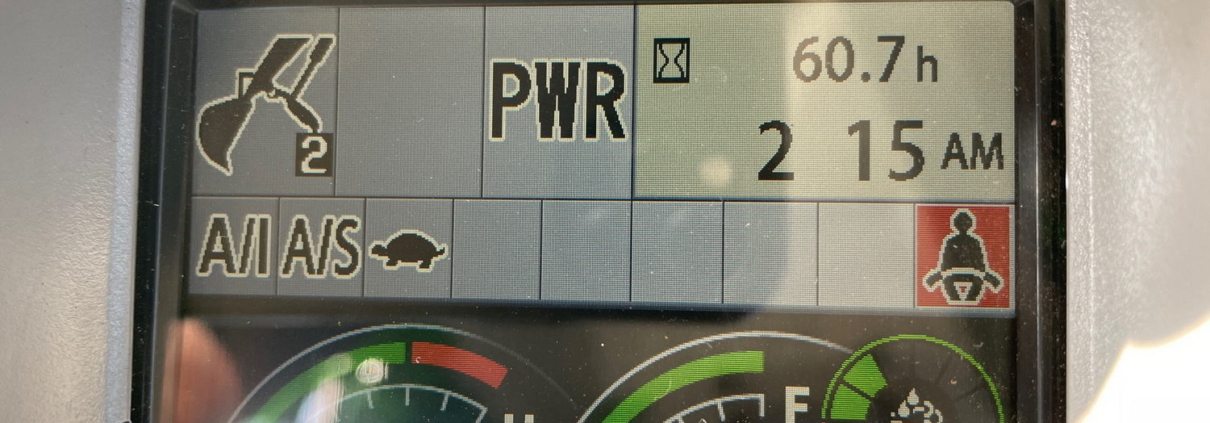

- Daily Inspections: We should conduct daily inspections to identify any signs of damage or wear, focusing on components such as the undercarriage, hydraulic system, and attachments.

- Scheduled Services: Adhering to the manufacturer’s service schedule is imperative for long-term maintenance and includes deeper checks and replacements of parts at predefined intervals.

Detailed Component Care

In maintaining excavator parts, we direct our focus on the longevity and reliability of our machines. Proper care in specific areas is crucial for reducing wear and preventing costly breakdowns.

Undercarriage Maintenance

We prioritize undercarriage maintenance as it carries the weight of the excavator and is subjected to constant movement. Key points to remember include:

- Tracks: Regularly check track tension and adjust as necessary to prevent excessive wear.

- Rollers and Idlers: Ensure these components are clean, and rotate smoothly. Replace them when signs of wear are visible.

- Sprockets: Inspect for worn or broken teeth. Sprocket misalignment can drastically increase wear on your tracks.

Cleaning: At the end of each day, remove debris from the undercarriage to avoid buildup that can cause premature wear.

Engine and Hydraulic System Care

The heart of the excavator, the engine, and its closely integrated hydraulic system require diligent care for optimum performance.

- Engine Maintenance: Regularly check and maintain proper coolant levels. Replace the engine’s fuel filter and air filters according to the service schedule to ensure effective combustion and minimize contaminants.

- Hydraulic Fluid: Consistently monitor hydraulic fluid levels. Look for signs of contamination that could signal leaks or component wear.

- Filters: Replace hydraulic filters at recommended intervals to prevent contaminants from circulating and causing damage to sensitive components.

Electrical and Structural Integrity

Electrical systems and structural components must not be overlooked as they’re integral to the excavator’s functionality and safety.

- Electrical Components: Inspect wiring and connections for signs of corrosion or damage. Ensure that battery connections are clean and tight to prevent power loss.

- Structural Inspection: Regularly inspect the excavator’s boom, arm, and bucket for structural integrity. Address any cracks or wear immediately to maintain the machine’s structural stability.

Operational Best Practices

In ensuring the longevity of excavator components, we must adhere to operational best practices. These practices not only preserve the machinery but also enhance safety and efficiency on the job site.

Optimal Operating Techniques

We recognize that meticulous operation significantly reduces wear and contributes to equipment longevity. Here’s how we maintain high performance:

- Avoid Overloading: We ensure that load limits are strictly followed to prevent mechanical strain and potential structural damage.

- Smooth Operating: Our operators are trained to handle the controls with finesse, avoiding jerky movements that can increase stress on components.

Managing Environmental Impact on Excavators

The environment plays a crucial role in the life expectancy of excavator parts. Here’s what we do to mitigate negative impacts:

- Weather Adaptation:

- Dry and Dusty Climates: We increase cleaning frequencies to reduce the abrasive effects of dust on moving parts.

- Wet Conditions: We pay special attention to drainage and drying to prevent rust and corrosion. Proper storage away from the elements is essential.

- Site Conditions: On construction or mining sites, we make it a point to clear debris from the undercarriage and other components daily to prevent build-up and wear.

Repair and Replacement Strategies

To ensure the longevity and reliability of excavators, we must adopt strategic repair and replacement methods. By doing so, we minimise downtime and prevent costly repairs.

Identifying Common Wear and Potential Hazards

We regularly inspect our excavators to identify common wear and potential hazards, such as leaks or cracks that may indicate the need for immediate attention. Our checks include:

- Hydraulic systems: We look for signs of leaks and ensure hydraulic fluid is at the correct level.

- Undercarriage: This area is prone to wear; we check for loose bolts, worn sprockets, and track tension.

- Attachments: We inspect buckets and other attachments for damage or excessive wear.

Timely Repairs and Part Replacements

We adhere to a strict schedule for timely repairs and part replacements to avoid the escalation of damages. Here’s our approach:

- Filters and Fluids: We change oil and filters regularly and use the recommended grades to keep engines clean.

- Lubrication: To reduce friction and wear, we grease all moving parts at prescribed intervals or per the manufacturer’s guidance.

- Component Lifespan: As parts show wear, we replace them before they fail. This involves assessing the condition of replacement parts to ensure they are up to standard.

Each action we take is recorded meticulously to track the equipment’s repair history, improving our ability to predict and plan future maintenance needs. We aim to optimise the performance and extend the service life of our excavators by maintaining them well.