Excavator Common Issues and Solutions – Fix Your Digger Fast

Excavators are vital tools in construction, but they can sometimes act up. When your excavator won’t start or doesn’t work right, it can really slow down your job. Knowing how to fix common excavator problems can save you time and money on the worksite.

You might run into issues like engine starting problems or hydraulic system failures. These can be caused by things like bad fuel, worn parts, or lack of maintenance. The good news is that many of these problems have simple fixes you can do yourself.

Regular check-ups and care for your excavator can prevent a lot of headaches. By learning about common issues and how to solve them, you’ll keep your machine running smoothly and your projects on track.

Key Takeaways

- Regular maintenance prevents many common excavator issues

- Simple troubleshooting can often fix problems quickly

- Proper care of your excavator keeps job sites running smoothly

Diagnosing Excavator Issues

When your excavator acts up, it’s crucial to pinpoint the problem quickly. Let’s look at common issues and how to tackle them head-on.

Identifying Common Excavator Problems

Keep an eye out for these tell-tale signs of trouble:

- Jerky movements

- Loss of power

- Unusual noises

- Slow response times

- Visible leaks

These symptoms often point to bigger problems. Pay attention to when they occur and what you were doing at the time. This info will help you or a mechanic figure out what’s wrong faster.

Hydraulic issues are a frequent culprit. Check for leaks around hoses and fittings. Low fluid levels can cause jerky movements.

Undercarriage troubles might show up as weird noises or vibrations. Inspect tracks for wear and tear regularly.

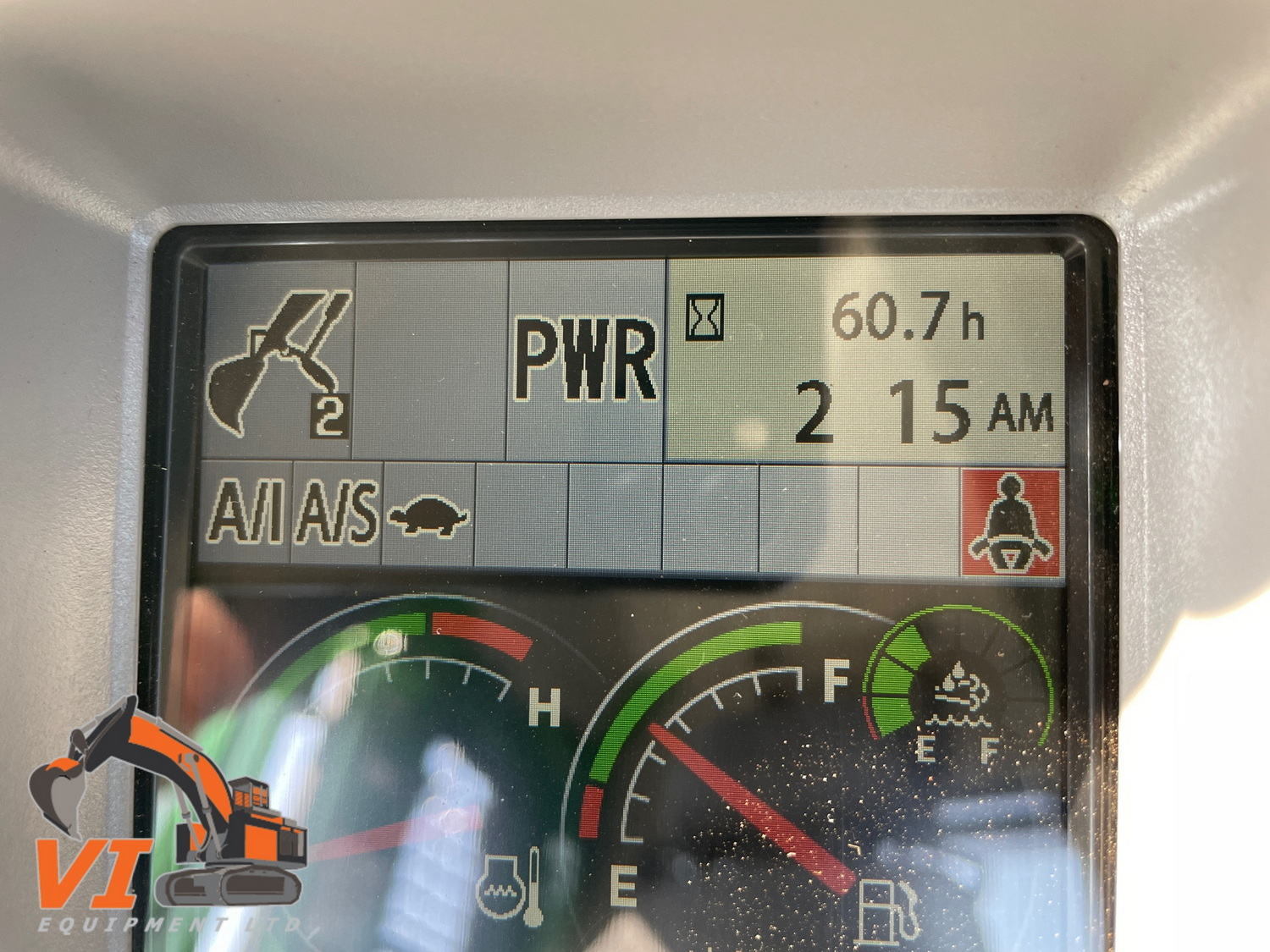

Addressing Engine Trouble

If your excavator won’t start or loses power, you might have engine problems. Here’s what to check:

- Fuel system: Look for dirty fuel or clogged filters.

- Air intake: A blocked air filter can choke the engine.

- Cooling system: Overheating is bad news. Check coolant levels and the radiator.

Listen for unusual sounds when the engine’s running. Knocking or ticking noises often mean serious issues.

If the engine starts but lacks power, you might have compression problems. This needs a pro’s touch.

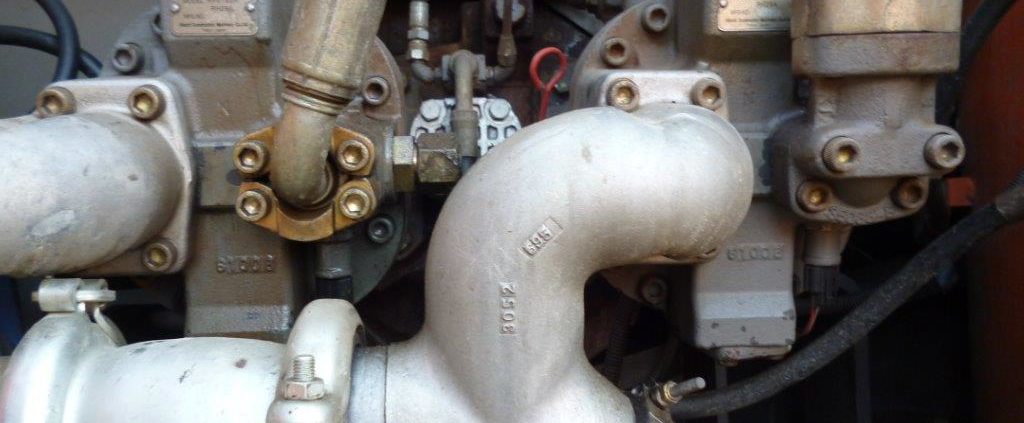

Troubleshooting Hydraulic System Failures

Hydraulics are the muscles of your excavator. When they fail, you’re in for a tough time. Here’s how to spot and fix issues:

- Check hydraulic fluid levels daily.

- Look for leaks around cylinders, hoses, and fittings.

- Listen for weird noises from the hydraulic pump.

Low fluid levels can cause jerky movements or slow response. Top up if needed, but find the leak source too.

Hydraulic pump failure is serious. Signs include loss of power and strange noises. If you suspect this, stop work and call a pro.

Worn seals can lead to internal leaks. This causes a gradual loss of power. Regular maintenance can catch these early.

Fixing Electrical System Malfunctions

Electrical problems can be tricky. They often cause intermittent issues that are hard to pin down. Here’s what to look out for:

- Check fuses first. A blown fuse is an easy fix.

- Inspect wiring for damage or loose connections.

- Test the battery. A weak battery can cause all sorts of trouble.

Corroded connections can mimic more serious issues. Clean and tighten all electrical contacts regularly.

If controls are acting up, it could be a sensor problem. Modern excavators rely on lots of sensors. A faulty one can throw everything off.

For complex electrical issues, you’ll need a diagnostic tool. This can read error codes and point you in the right direction.

Maintenance and Preventative Measures

Taking care of your excavator is key to keeping it running smoothly. Regular upkeep and using top-notch parts can save you time and money in the long run.

Implementing Regular Maintenance Routines

Set up a maintenance schedule for your excavator. Check fluid levels daily, including engine oil, coolant, and hydraulic fluid. Top them up as needed.

Grease moving parts weekly. This helps reduce wear and tear on your machine.

Inspect the tracks monthly for proper tension and wear. Adjust or replace them if needed.

Clean the air filter regularly. A clogged filter can hurt engine performance.

Change oils and filters as per the manufacturer’s guidelines. This keeps your excavator running at its best.

Keep an eye on the battery. Clean the terminals and check the charge often.

Selecting Quality Replacement Parts

Choose parts from trusted brands or your excavator’s manufacturer. Cheap parts might save money now but can cost more later.

Look for parts with good warranties. This shows the maker stands behind their product.

Consider OEM (Original Equipment Manufacturer) parts. They’re made to fit your specific model.

Ask other operators which brands they trust. Their experience can guide your choices.

Check part reviews online before buying. This can help you avoid low-quality options.

Keep common wear items on hand. Having things like filters and belts ready can reduce downtime.